Recycling thermoset-based composites presents both technological and economic challenges due to the degradation of fibre properties (such as length and strength) and energy-intensive processes in common methods like mechanical recycling and

pyrolysis. Thermochemical recycling, which extracts reinforcing fibres from depolymerized matrices, offers an advanced solution that can recover high-quality fibres. However, additional processing is needed to use these fibres in new composites, particularly due to the removal of the fibre surface sizing, which impacts fibre-matrix compatibility, especially with glass fibres.

This seminar addresses the re-sizing of recycled fibres, introduces novel micromechanical testing methods for evaluating the fibre-matrix interface, and presents case studies demonstrating the use of recovered fibres in industrial applications, while emphasizing the need for further improvements in the recycling process.

To received the Zoom link please write by January 28 to comunicazione.dii@unitn.it.

Biosketch

Essi Sarlin is a Professor in Polymeric materials at Tampere University, in Finland. Her research focus includes the sustainability aspects of polymers and polymer composites. Specifically, recycling of fibre reinforced composites and the valorisation of recycled composite feedstock are her interests, and she has been working in related projects since 2017.

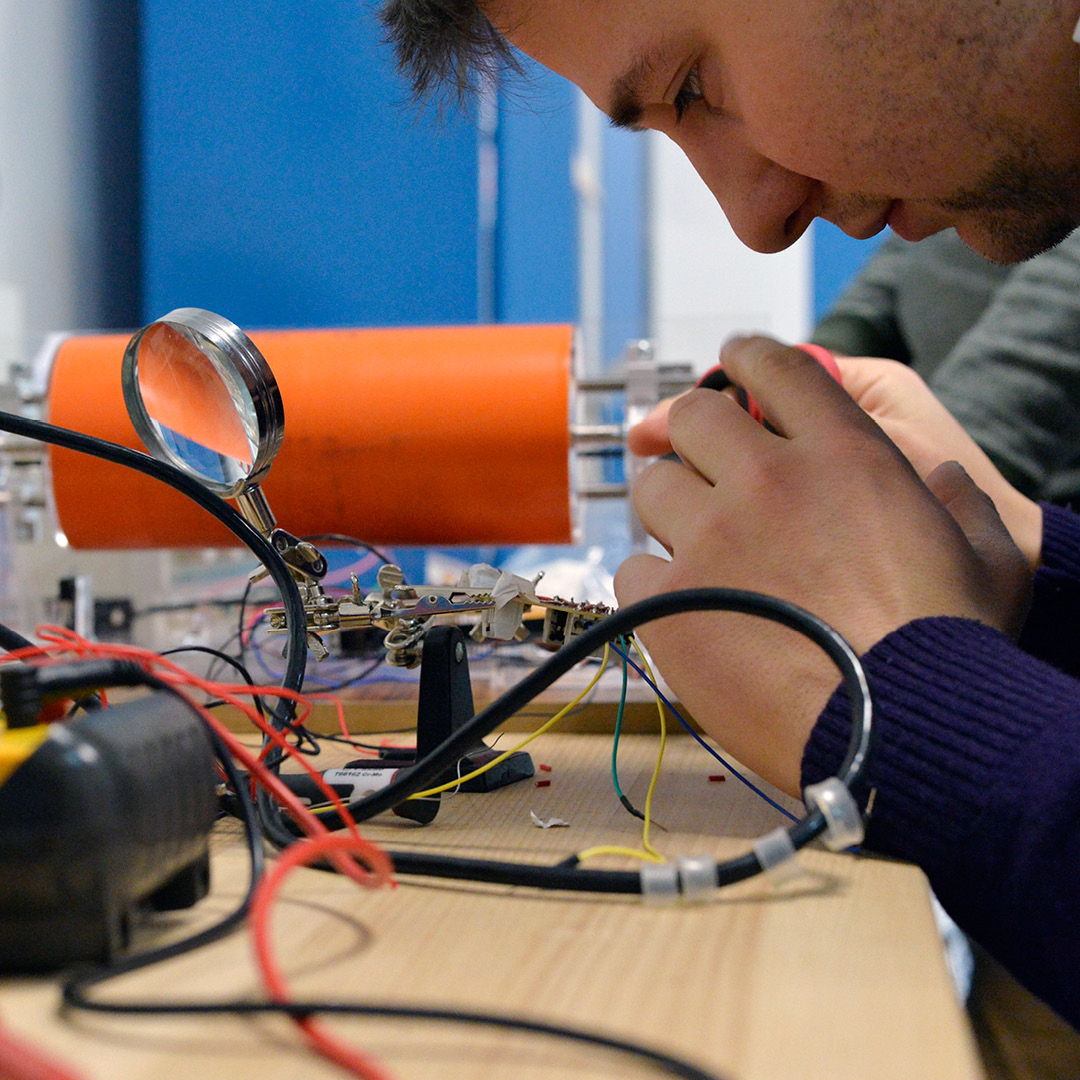

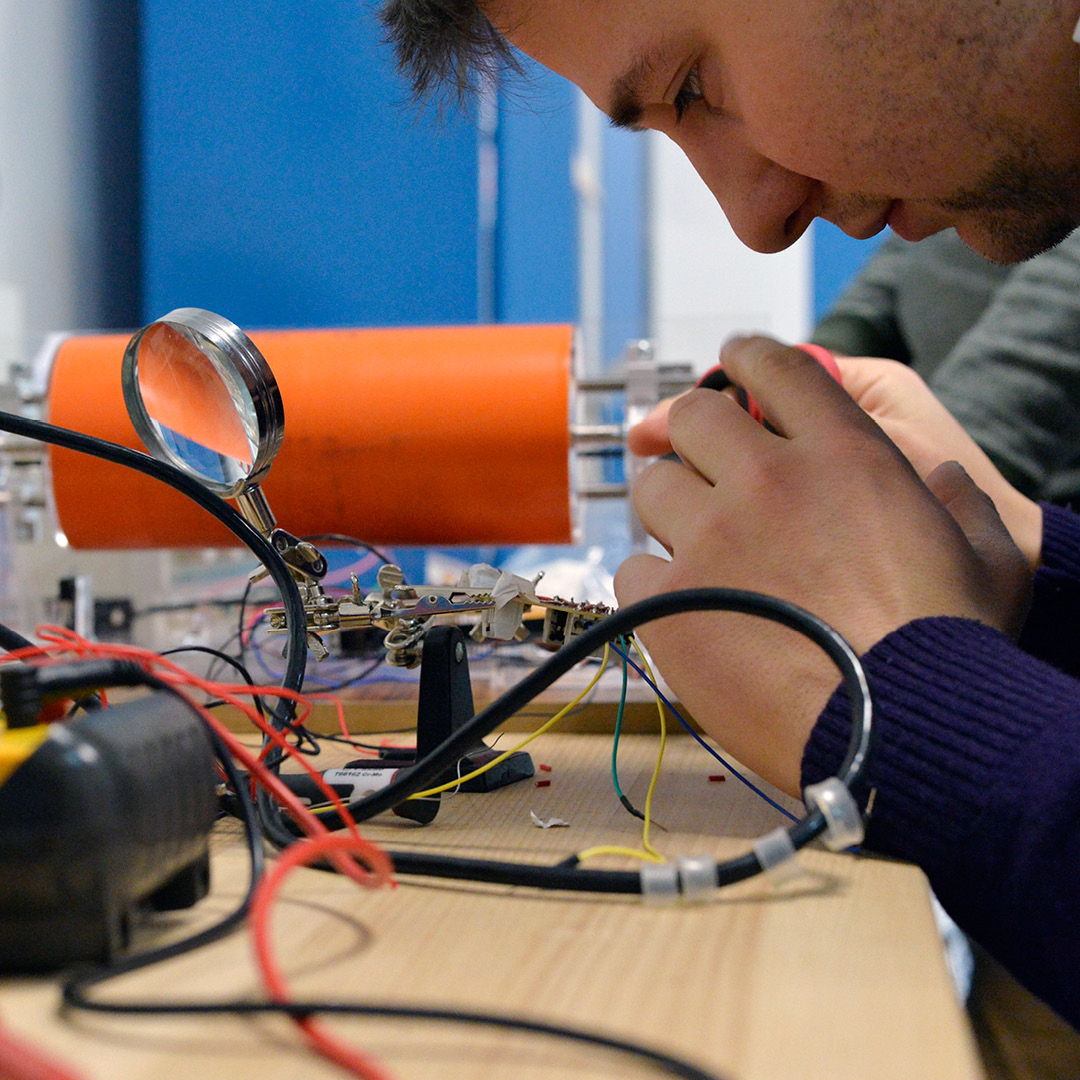

Her research group uses several established mechanical, thermal and chemical methods to characterize composite materials. In addition, they apply the so called microbond method, which allows collection of detailed mechanical data of fibre-matrix interface, which plays a key role in load transfer of composite materials.